Our Services

Analyses and Development

Elettroplast supplies a full service, from the analysis of the components, to the design of the mould, resulting in the customised moulded components delivered to customer’s production lines.

Our skilled staff have the expertise required to offer customers the right warranties for the SOP (start of production) of their products.

We work closely with our customers, performing the following step-by-step analyses:

- analyses of critical issues (thin, difficult to fill profiles, potential suction issues, risks of buckling etc.; analysis of undercuts and of the costs related to the type of mould movement necessary and the press required as a result);

- analysis of the design mould (verification of injection points, analysis of the type of extraction, the cooling process, and the mouldflow).

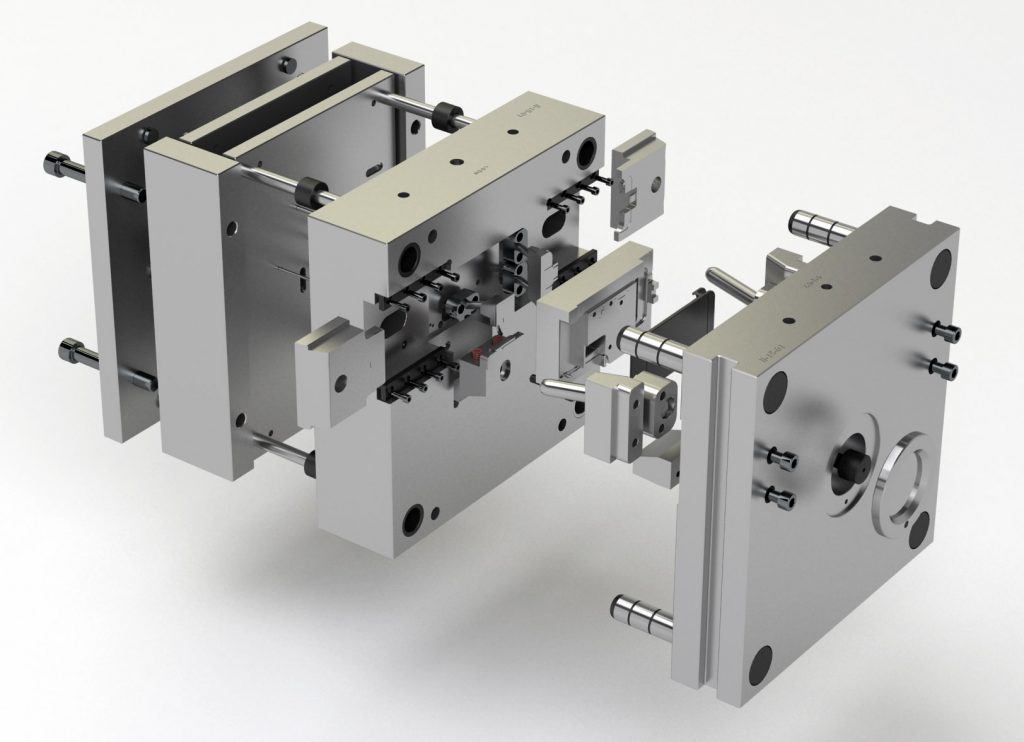

Injection mould manufacturing

Our moulds are manufactured by moulders certified by the company. These are selected based on the unique features of the designs: multi-cavity needs, micro-parts, bi/tri-materials, aesthetic or transparent details, and technical details (technopolymers and superpolymers).

The timing of the manufacturing process is constantly monitored by the project manager, who is in contact with the moulders and the customer on a day-to-day basis.

An important customer guarantee is the ordinary maintenance of the moulds, carried out internally in a department also equipped with a laser welder, enabling the prompt repair of the moulding parts.

Injection moulding

Our moulding department is highly automated. Specialised professionals use 51 Arburg injection-hydraulic and electric injection presses, covering a range that spans from 35 to 320 tons. All the presses have a 2 or 3-axle robotic gripping system; they also feature a press-side working area with an anthropomorphic robot for gripping and assembling parts.

Each press is served by control units for thermoregulating the moulds, which operate at high temperatures (when moulding superpolymers). In the department, employees work according to a three-shift rota to ensure the rapid execution of production orders and compliance with customer delivery times.

Our material transport and treatment system is one of the strong points of our new plant, designed from a 4.0 perspective. In fact, two sorting units are used to connect all the presses to the dehumidifiers and cold-material gripping points. The system also enables the constant monitoring of the press cooling system.

All this is transformed every day into efficiency and quality.

Treatments

On request, Elettroplast offers a range of component stabilising treatments to complete the moulding process:

- tempering furnaces, which guarantee the dimensional stability of the components over time, preventing subsequent shrinkages

- in-tank conditioning, which results in the hygroscopic saturation of materials, thereby increasing their mechanical characteristics and allowing them to be used immediately on customer lines.

Assembly and finishing

To ensure excellent customer support that meets the need for finished, tested sub-assemblies, Elettroplast offers assembly and finishing activities provided by its trusted, specialised sister company TechnoAssembly.

This guarantees:

• the traceability of the sub components used for the product;

• continuous and constant process monitoring;

• quality control and final testing.

The technologies used include three lasers for marking and customising the products and an ultrasound welder and gate tests to check the assembled sub-groups.

Painting, pad printing, screen printing and hot printing services are outsourced to company-certified suppliers, which are regularly inspected by Elettroplast.

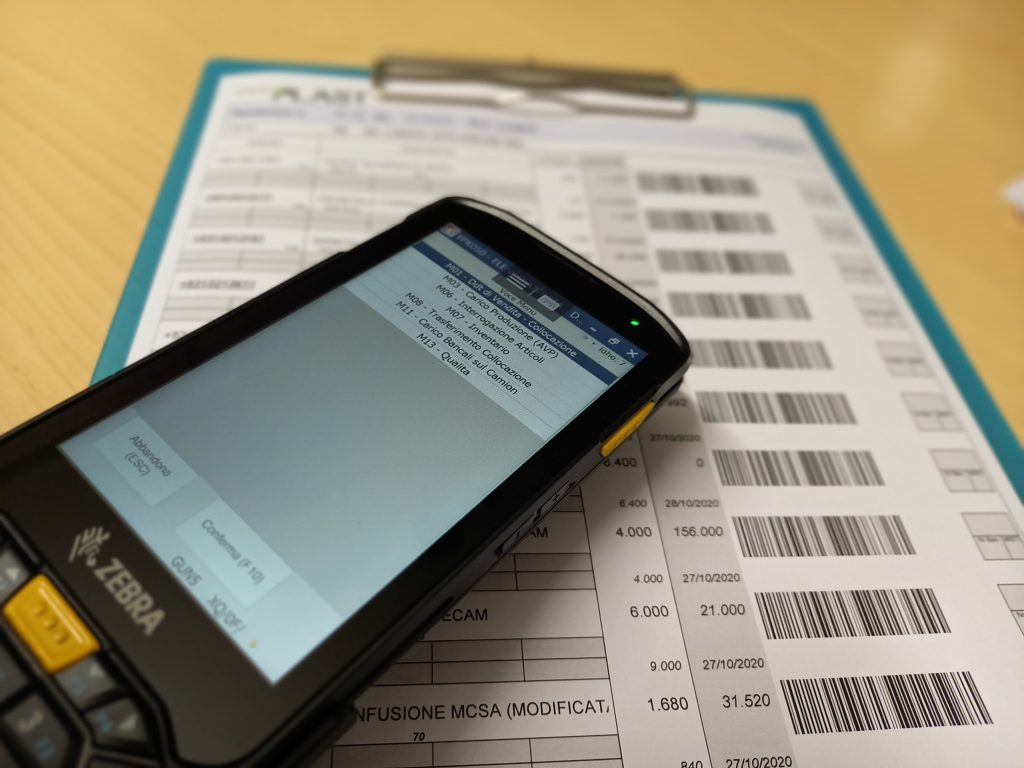

Logistics

Promptness and reactivity are two of the characteristics that make us stand out.

We start by correctly analysing and locating raw materials and finished product: logistics are therefore a fundamental aspect of our service.

We digitally manage loading and unloading operations from our warehouses, the creation of shipping and picking lists, as well as delivery notes for customers and suppliers, so guaranteeing accuracy and efficiency.