Quality

Quality: another word for reliability and performance

“Work well all the time” is exactly how Elettroplast applies the concept of quality to everything it does. Not as a barrier stuck at the end of the process to block everything that fails to meet the required production standards, but as the efficiency of all the processes involved in the company’s production chain.

For us, offering our customers a top quality service means correctly organising the production process from the very beginning, so avoiding production stoppages and having to repeat the production of non-conforming lots and so eliminating the inefficiencies that generate useless costs.

To guarantee our service, we dedicate the utmost care and attention to the following activities:

- analysing the designs;

- assessing the type of machinery and moulds required;

- monitoring the treatment and preparation of the raw materials;

- checking the moulding process;

- analysing the most suitable packaging types and storage conditions;

- certifying the product with the proper reports.

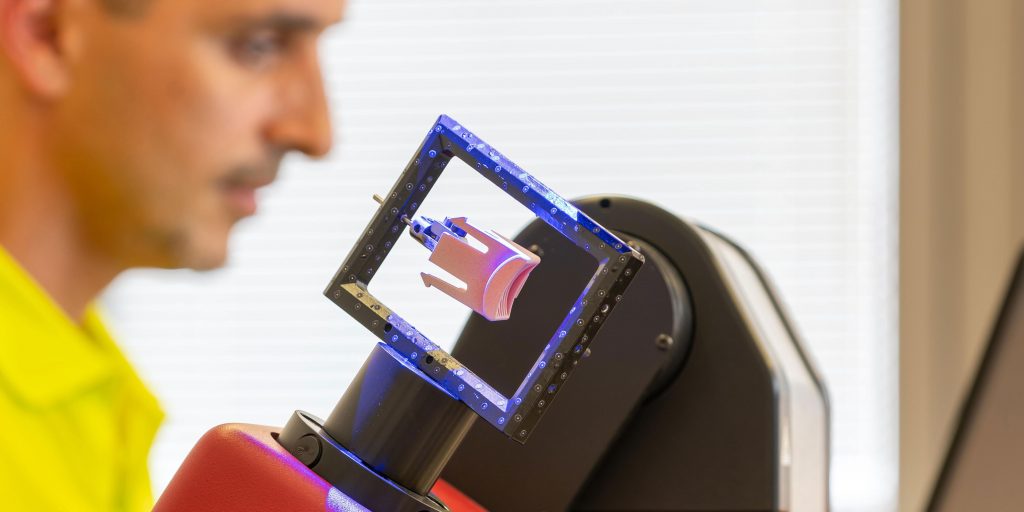

- scansione 3D con luce strutturata (Sistema ATOS CORE),

- Proiettore di profili digitale – Keyence IM-8030T

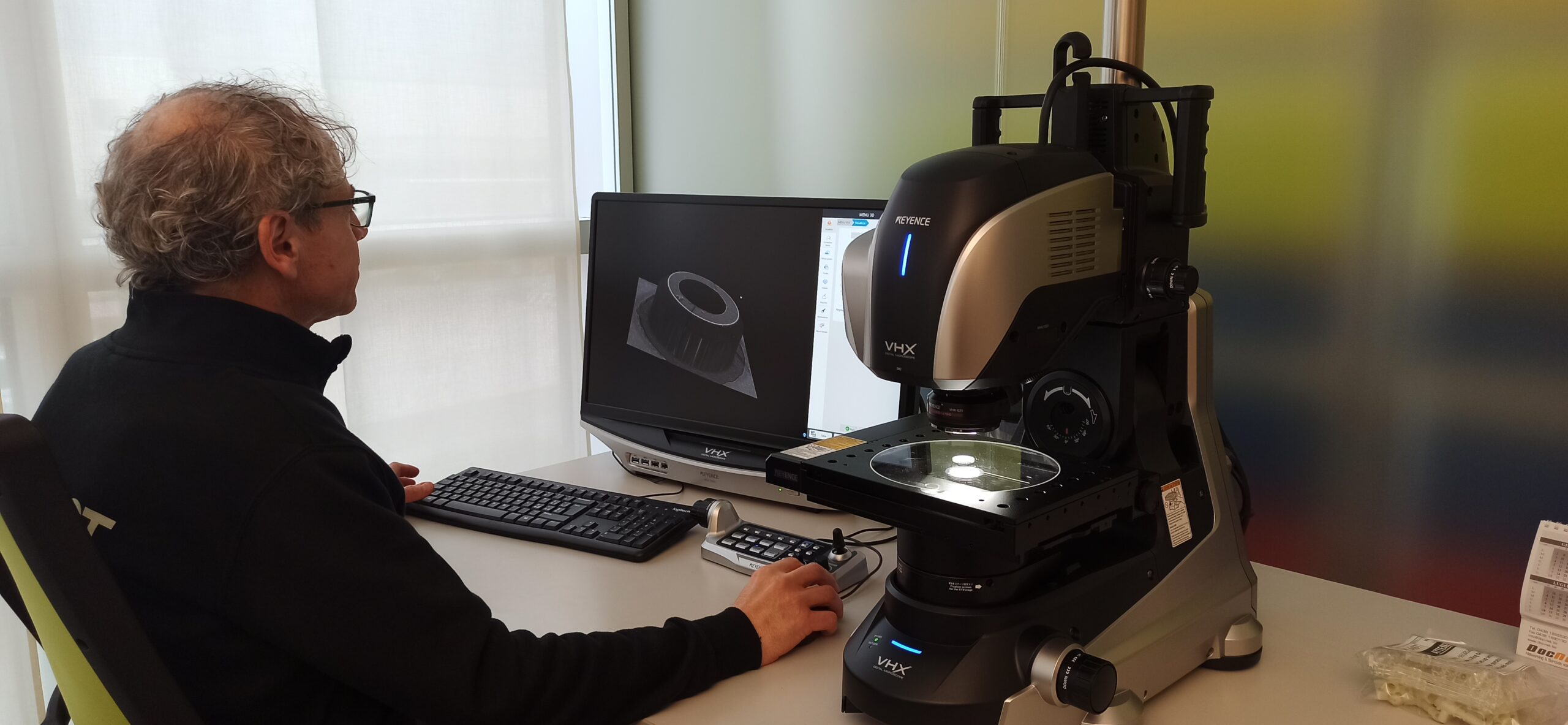

- Microscopio digitale – Keyence VHX-7000N

The Elettroplast production process has also been certified, and is constantly monitored by our major customers

Obiettivo importante sarà il conseguimento della certificazione ISO 45001 per il 2026..